Harvest & Milling

Modern olive oil harvesting and pressing are carried out carefully to ensure the highest quality of the final product. Here are the key steps in a harvesting and pressing process that follows high quality standards:

Choice of the right time for harvesting

Olive harvesting is a key factor in obtaining high-quality olive oil. The ideal time for harvesting varies depending on the type of olive, but is primarily based on the color of the fruit, oil content, and ripeness.

EARLY HARVEST: If you're looking for an olive oil with more flavor, fruitiness, and a higher concentration of antioxidants, harvest early when the olives are still at their green ripeness.

LATE HARVEST: If you prefer a milder oil, you can wait until the olives ripen further and acquire a darker (black) color.

Mechanical or manual harvest

There are two harvesting methods: manual and mechanical.

MANUAL HARVEST: It is carried out by hand-picking the olives, which is less damaging to the fruit and preserves its quality. It is ideal for areas where mechanization is difficult or for olive groves where a higher-quality harvest is desired.

MECHANICAL HARVESTING: It uses vibrating machines that shake the olive trees and cause the olives to fall onto tarps or nets. This method is quick, but must be done carefully to avoid damaging the fruit.

FAST TRANSPORT TO THE MILL

The olives must be transported to the mill as soon as possible after harvesting. This is crucial to prevent the olives from fermenting or deteriorating, which could affect the quality of the oil. In some cases, the harvest is taken directly to the mill on the same day.

CLEANING THE OLIVES

Before pressing, the olives must be cleaned to remove impurities such as leaves, branches, and soil. This process is carried out in a washing machine that uses cold water to ensure the oil is not contaminated by external elements.

Grinding or crushing olives

The cleaned olives are crushed in a stainless steel mill to obtain an olive paste. This step must be done carefully to avoid overheating the paste, as excessive heat can affect the quality of the oil.

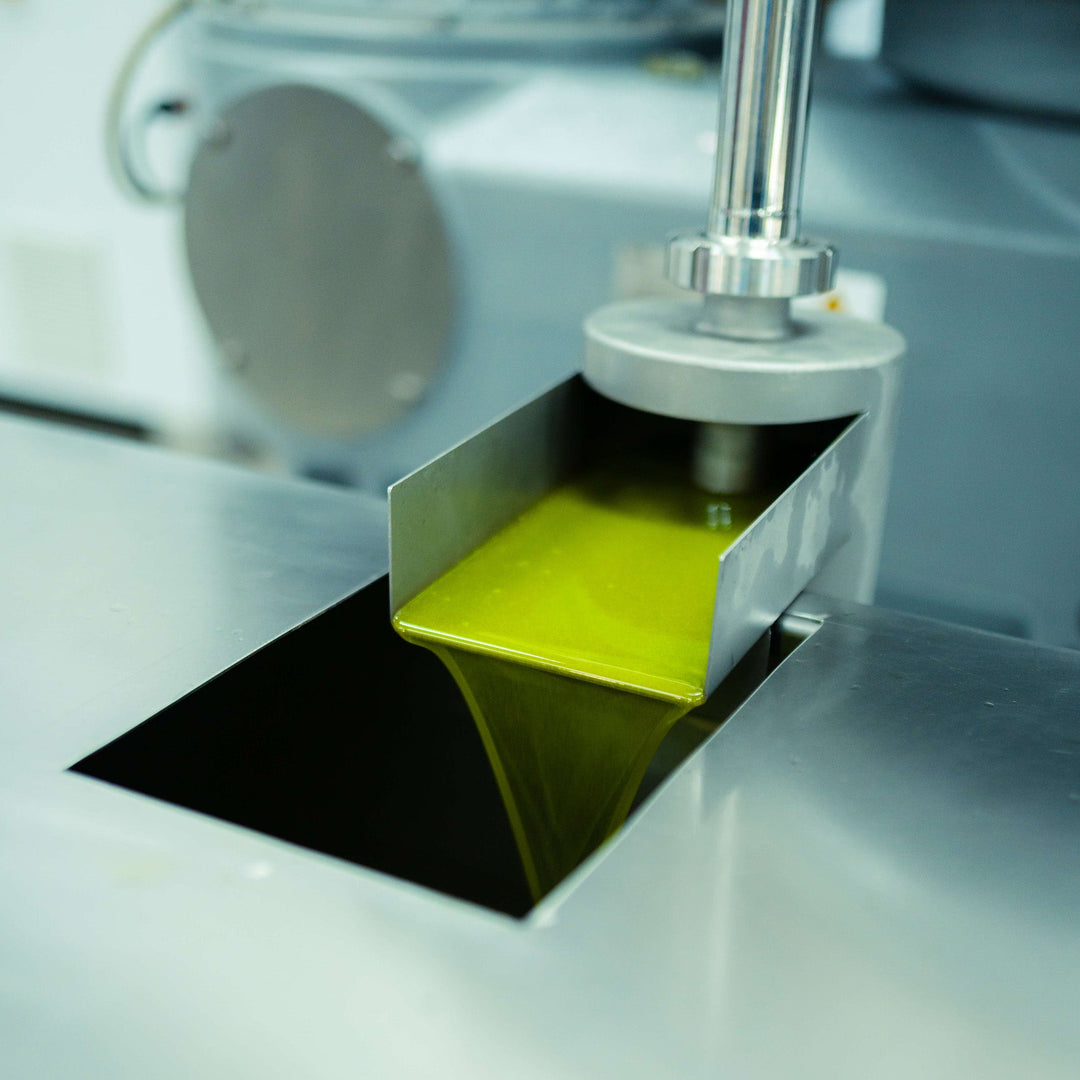

Oil extraction

Cold extraction with centrifugation: This is the most common method for producing high-quality olive oil. A centrifuge separates the oil from the olive paste using centrifugal force. This process is carried out at low temperatures (generally below 27°C), which is known as "cold extraction." This preserves the oil's flavors, aromas, and nutritional properties.

DECANTATION AND FILTERING

After extraction, the crude oil is decanted to remove any remaining water and solid particles. In many cases, the oil is filtered to ensure it is completely clean and free of impurities.

PROPER STORAGE

Olive oil must be stored under proper conditions to prevent spoilage. Containers should be made of stainless steel to prevent exposure to light and air, which can oxidize the oil. It is also important to keep the oil in a cool place (below 20°C) and away from heat sources.

QUALITY CONTROL

Throughout the entire process, quality controls must be performed to ensure the oil meets the required standards. This includes chemical component analysis (such as fatty acid and polyphenol content), sensory testing to evaluate flavors and aromas, and acidity checks to ensure the oil is extra virgin.

Conclusion

The modern olive oil harvesting and pressing process is a series of delicate and controlled steps to ensure the highest quality. From choosing the right harvest time to cold extraction and proper storage, each phase is crucial to obtaining the highest quality extra virgin olive oil. Care at each stage ensures that the final product retains all its organoleptic and nutritional benefits.